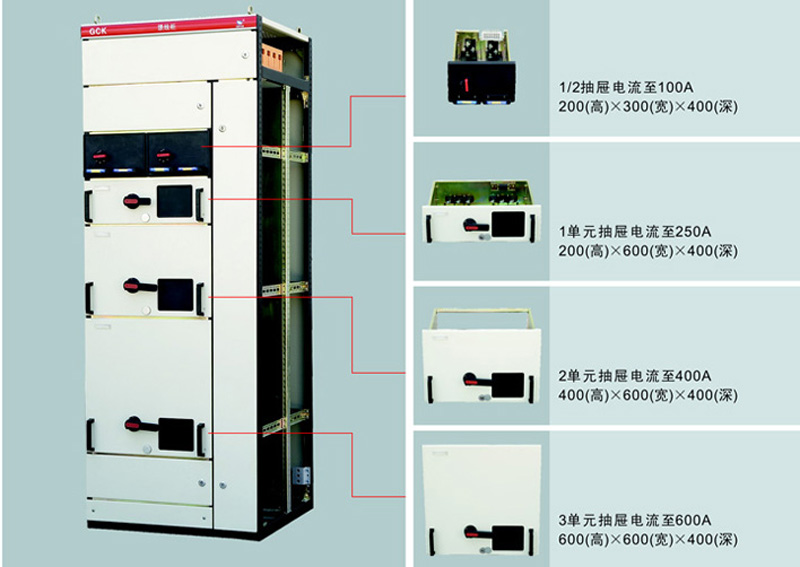

HLGCK low-voltage drawer type switch cabinet for three-phase AC 50,60HZ, 660V rated voltage and rated current 4000A and below the three-phase four wire system and three-phase five wire of power system, as acceptance of electric energy and distribution of electric energy use. Widely application in power plant, substation the, factories and mines and high layer building power distribution center PC and motor control center MCC.

1 meet the standards

This product conforms to:

National standard GB7251.1-2005< low voltage switchgear >;

National professional standard ZBK36001< low voltage draw out switchgear > JB/T9661-1999;

The international standard IEC439-1< low voltage switchgear and control equipment.

2 normal operating conditions

1 ambient air temperature is not higher than +40 C; not less than -15; and within 24 hours of its average temperature is not higher than +35.

2. The ambient air relative humidity at the highest temperature is 40 DEG C does not exceed 50%, to allow a larger relative humidity in low temperature, such as 20 DEG C for 90%, but should be taken into account due to the temperature change is likely to cause moderate gel accidental.

3 for indoor use, use the site altitude not exceeding 2000m.

4 should be installed in the absence of severe vibration and shock and not enough to use the electrical components of the corrosion sites.

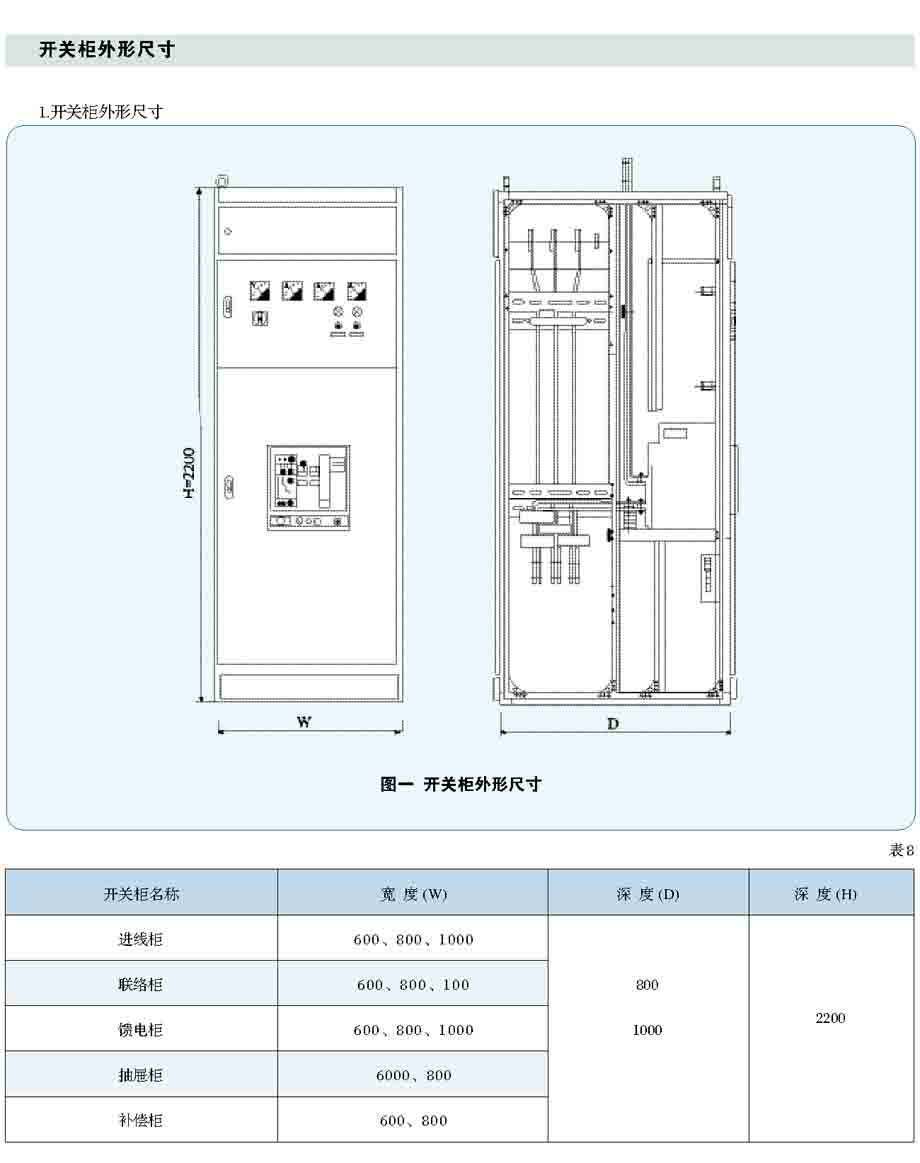

3 switch cabinet outline dimensions Fig.

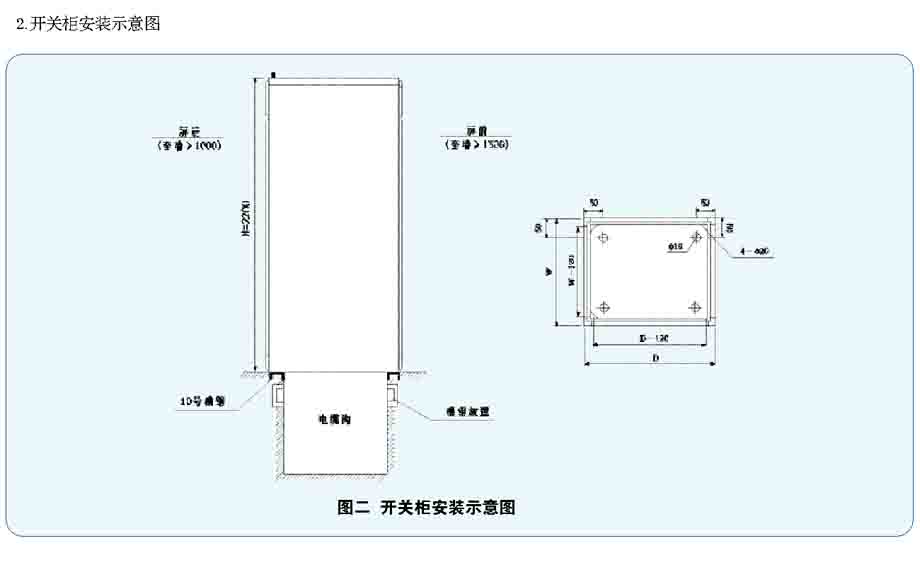

4 Schematic diagram of the switch cabinet installation

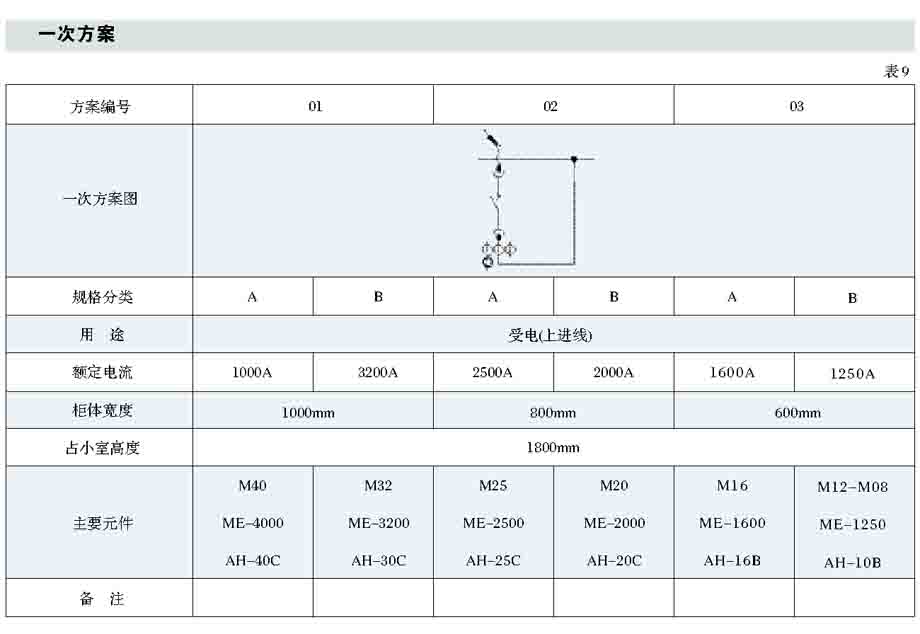

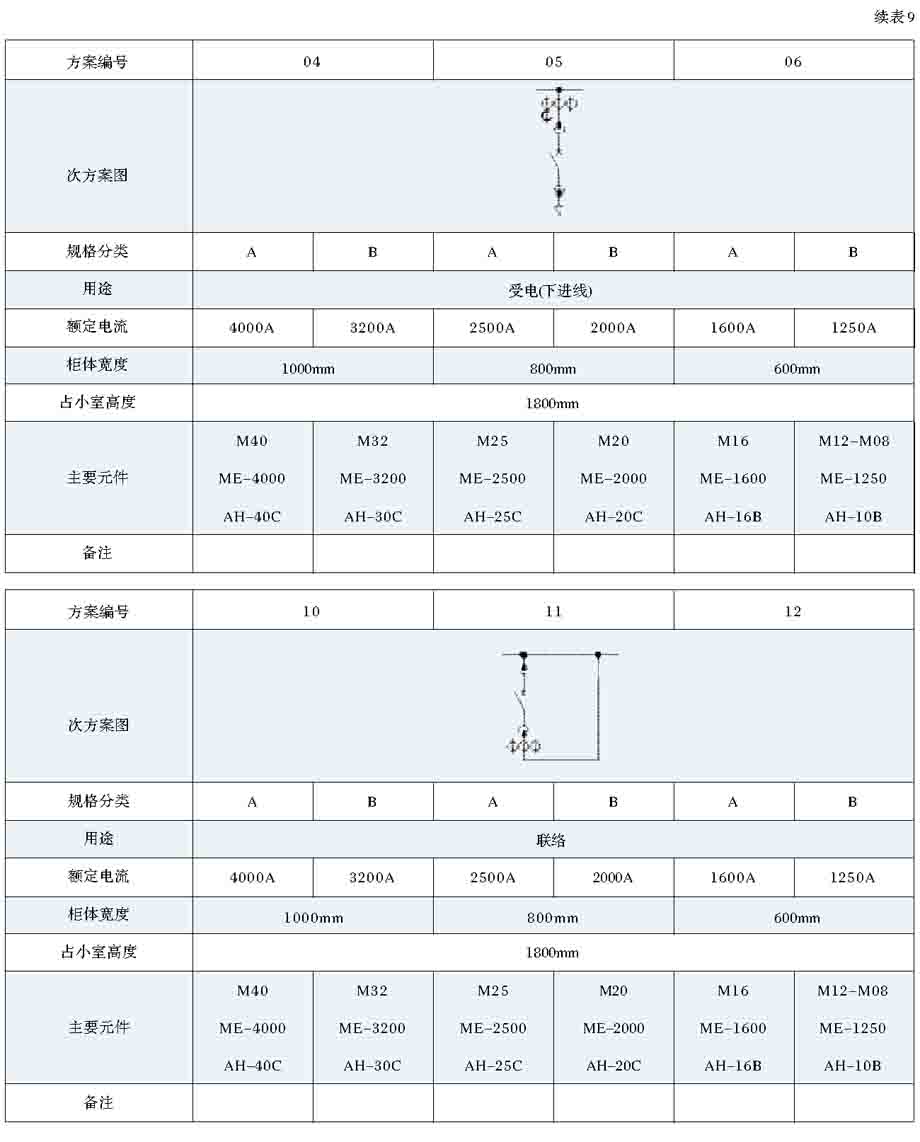

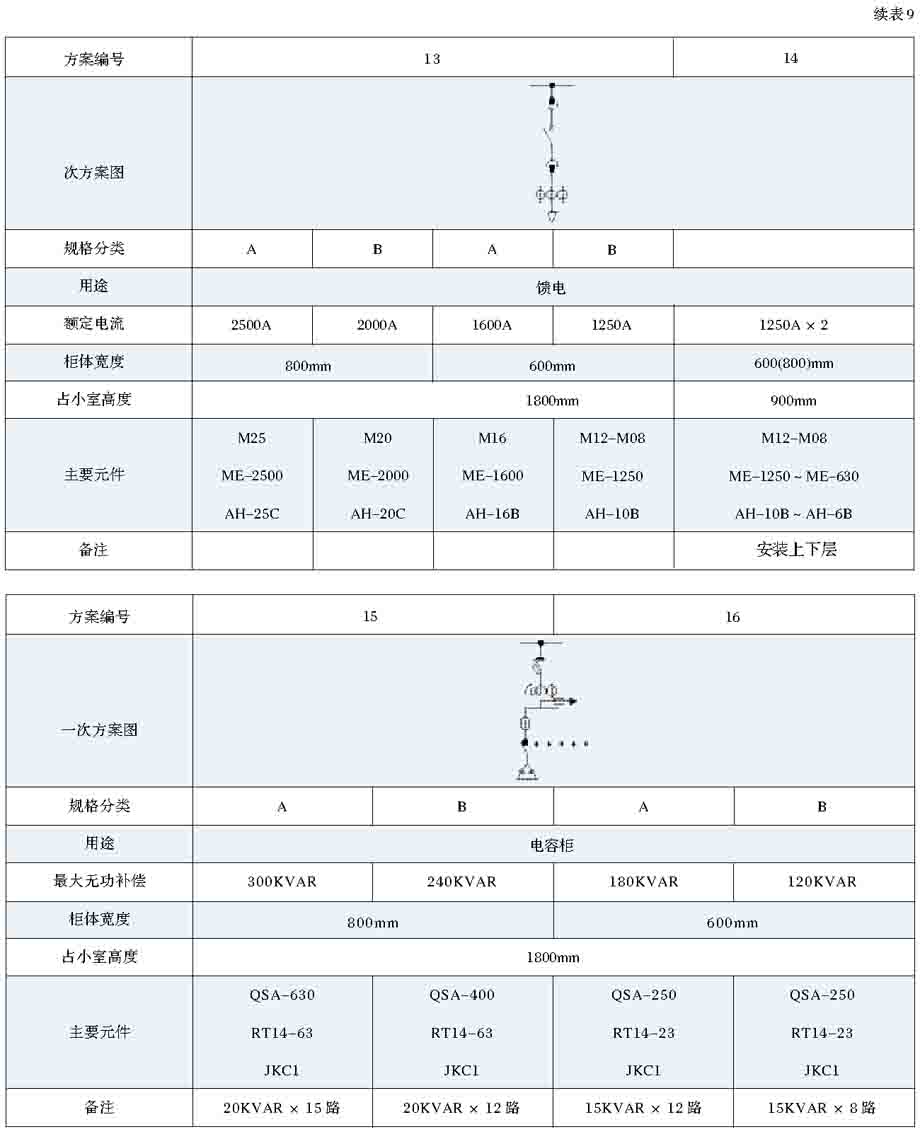

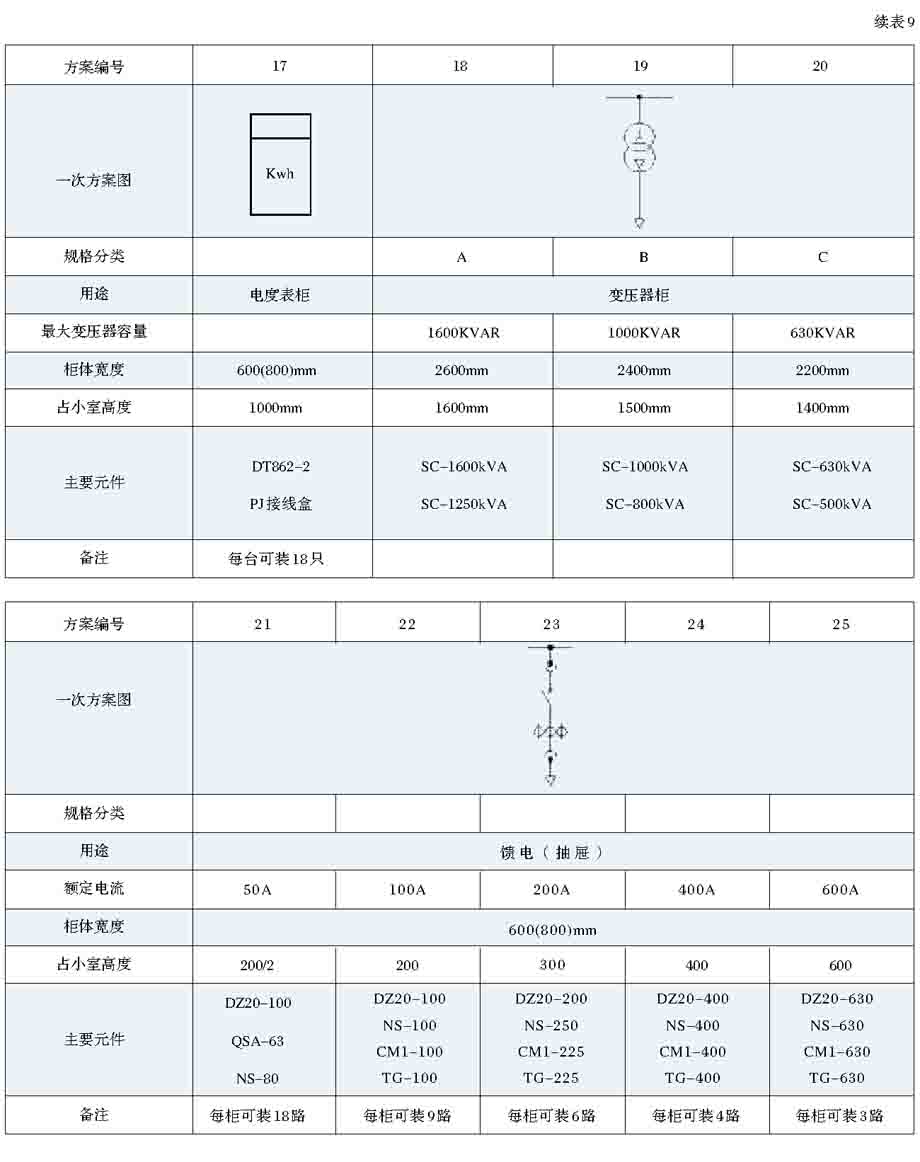

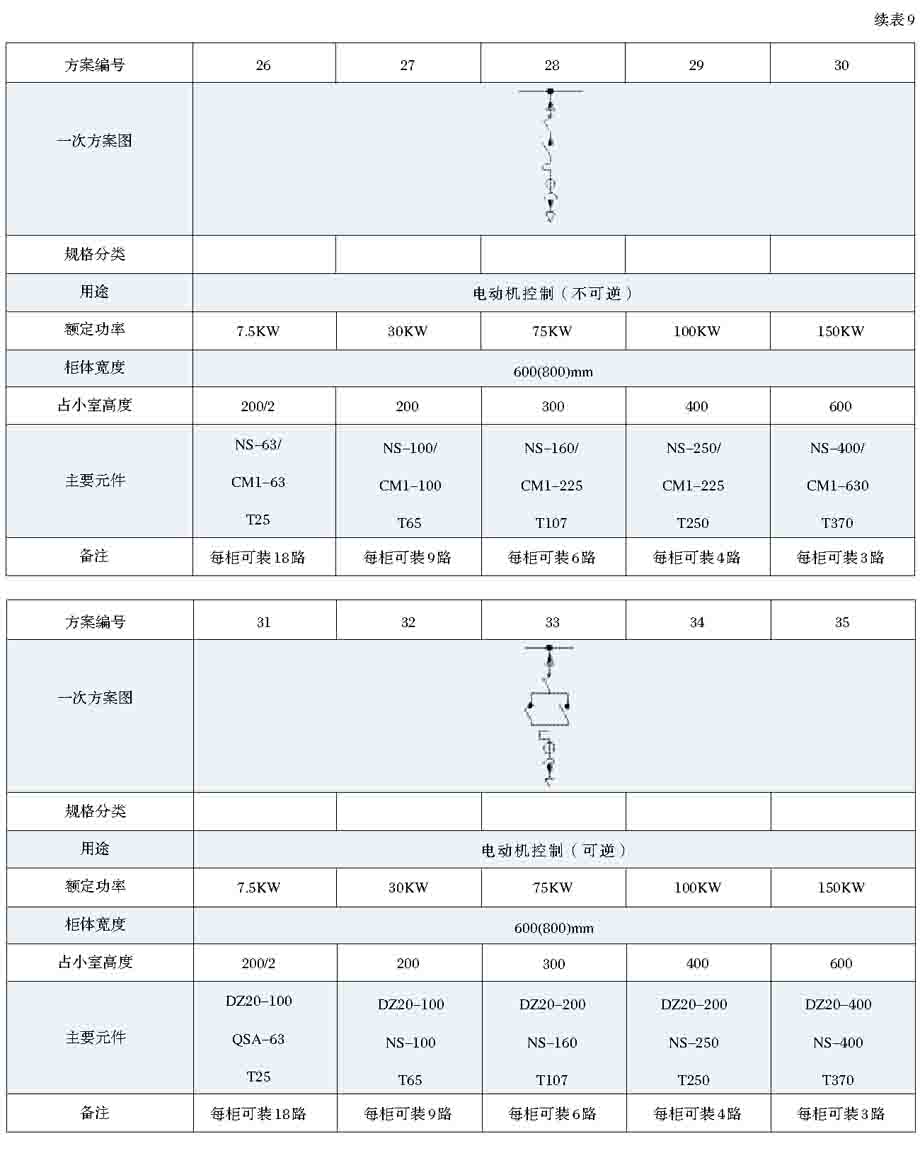

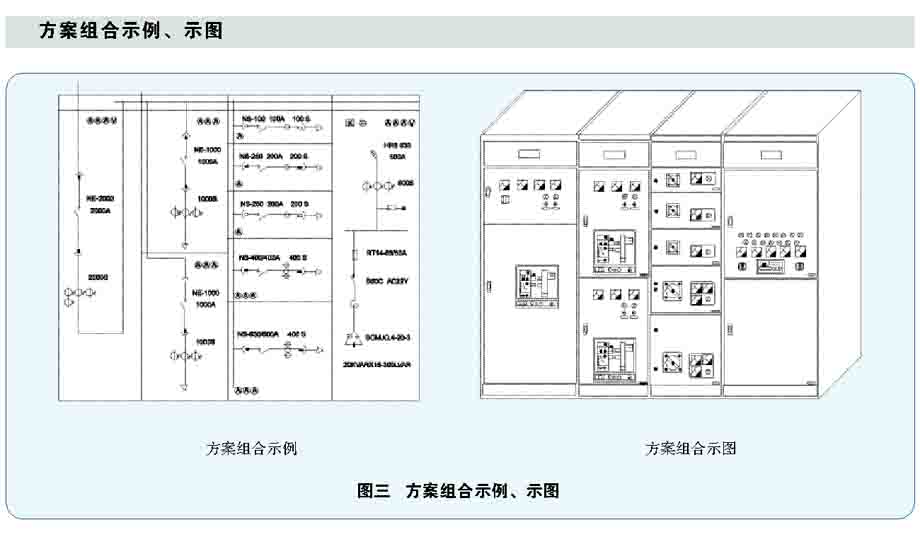

5 a program

6 portfolio example, showing the figure

7 installation and use

9.1 product installation should be according to distribution equipment general installation method, the foundation channel steel and the fixed mode of the bolt bolt owned by the user. For busbar connection, must make lap jointing, flat, or loosen the spell cabinet bolt to adjust.

Collision 9.2 products installed after put into operation before the inspection and test, check the cabinet surface covering material (such as spray) is not damaged, the cabinet is dry, clean and tidy; check the cabinet whether placement of foreign material (such as bolts, welding electrodes, each screw fastening loose and leak tighten; check the operating mechanism is flexible, the drawer is inserted in the card blocking phenomenon, the agency chain is reliable, the action is accurate; check switch setting current value, instrument calibration, transformer ratio and polarity is consistent with the requirements. Finally 1o00 megohm meter to measure the insulation resistance should not be less than 1 megohm, temporary power transmission, electric points, the index should be accurate without any error.

9.3 put into operation should keep daily maintenance and regular observation bus fever, found a high temperature rising or abnormal sound should identify the reasons. Depending on the operating environment factors, every 2 to 5 years for cleaning and maintenance work.

9.4 use note:

A. the GCK family cabinet is not against the wall installation, positive operation, double-sided repairs of low-voltage distribution cabinet. Cabinet maintenance channel and a cabinet door must is passing the examination of qualified personnel can enter or open operation, inspection and maintenance.

B. air circuit breaker, molded case switch after several minutes, especially through a short circuit, after will make contact local burn and produce carbon material, so as to increase the contact resistance, circuit breaker according to instructions for maintenance and repair;

C. After installation or repair, we must strictly check the compartment between the functional units of the isolation situation has been restored, in order to ensure good functional separation of the device, to prevent the expansion of the fault.

8 complete sets of products

The following documents and accessories shall be provided for the supply of the manufacturing plant:

A. delivery list;

B. product qualification certificate;

C. product samples;

D. factory inspection report;

E. a system diagram, control schematic diagram and the two wiring diagram;

F. door key, spare parts and operating handle contract provisions;

G. the main components of the instruction manual.

9 ordering instructions

The following information shall be provided for the user's order:

A. main circuit scheme and combination arrangement;

B. auxiliary circuit control and wiring principle;

Plane layout of C. switch cabinet in distribution room;

D. incoming and outgoing forms and interface requirements;

Detailed specifications and parameters of the components in the E. cabinet;

F. switch cabinet surface paint color, or by my company standards.