HLGN (XGN port) -24KV box type fixed high voltage switch cabinet

Summary:

XGN15 24 box type switch cabinet is applicable to 24KV three-phase AC 50Hz single, double bus system, as the receiving and distribution of electric energy use. The switch cabinet for indoor device, system does not rely on wall installation. Especially for frequent operation of the occasion.

Scope of application: This is a closed switch device in small current specifications in XGN15 24 box type fixed metal. This product conforms to GB3906 - 91<3 - 35kV AC metal closed switch equipment.

Product use environmental conditions:

And the ambient temperature: the upper limit of +40 C; the lower limit of 10;

Altitude is not more than 1000m;

Relative humidity: daily average of not more than 95%, the monthly average of not more than 90%;

There are no more than 8 degrees of earthquake crack; no fire, explosion danger, serious pollution, chemical corrosion and violent vibration;

- gel and polluted conditions applicable as follows, usually do not appear dew (annually not more than two times), but there is a serious pollution, gel or less frequent (per month more than two times), but only slightly contaminated. (i.e., accord with GB3906 - 91 of the regulations in Appendix E severity of level 1 conditions use)

Product series and main specifications:

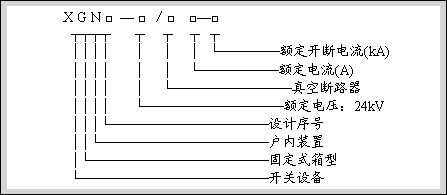

1, model composition

2, series and main specifications

Main wiring scheme and specifications

Technical parameter:

Project unit data

Product appearance and structure:

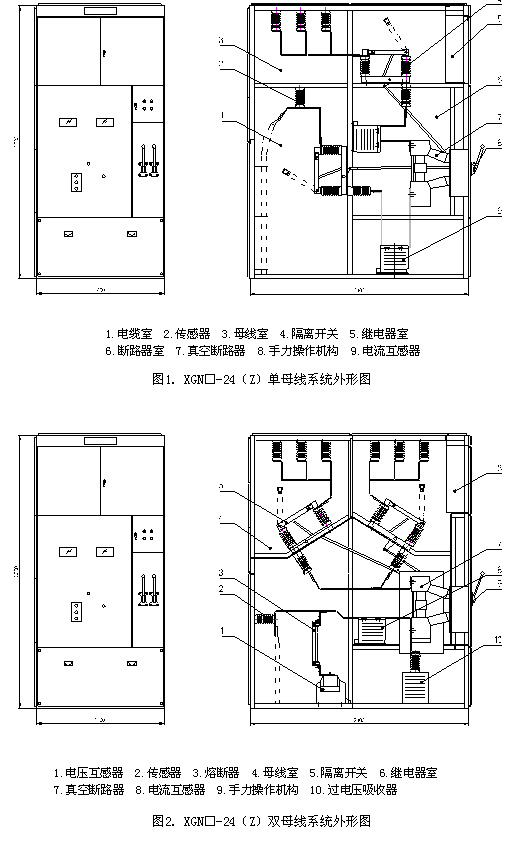

1, the product appearance (with vacuum circuit breaker as an example, see Figure 1, figure 2).

2, the installation size of the switch cabinet is shown in Figure 3

3, summarizes the structure

The switch cabinet for the closed metal box type structure, the cabinet body frame is composed of angle steel welded together, the cabinet can be divided for the circuit breaker room, the busbar compartment, relay room. Room and room between steel

Plate separated.

Circuit breaker chamber in the lower part of the cabinet body, drive circuit breaker by the pull rod and the actuating mechanism is connected, connection circuit breaker wiring terminal and a current transformer, current transformer and lower isolating switch connected with a wiring terminal, circuit breaker wiring terminal and the isolation switch terminals are connected, the circuit breaker chamber is also provided with a pressure release channel, if internal arc gas may release the pressure through the exhaust channel.

Switch cabinet for double maintenance, components of front inspection relay room, maintenance operating mechanism, mechanical interlock and the transmission part, maintenance circuit breaker behind maintenance mistress

Wire and cable terminal.

The lower part of the back door is provided with a grounding copper bus which is parallel to the width direction of the cabinet. The cross section is 4 * 40mmz..

Mechanical interlocking: in order to prevent the on load isolating switch; prevent misclassification circuit breaker; to prevent mistakenly charged interval; prevent with charge grounding switch; prevent with a grounding knife switch.

Installation, adjustment and maintenance:

1, installation

Vacuum circuit breaker switch on / off of dynamic load, to, down about 9840N, this data provides design basis when estimating the foundation stress.

(1) the basis of

Switch cabinet basic reference Figure 3 for design and construction, the foundation should be flat.

(2) installation procedures and matters needing attention

The switch cabinet placed on the foundation according to the order, adjustment of grouping switch cabinet straightness, verticality, level, then with M12 bolts or welding method

The switchgear is fastened on the steel base;

And M12x 30 bolts of connection between cabinet. Installation of busbar, open busbar chamber top cover for installation, after installation fastening top cover, connected to the busbar contact surface should be smooth, no dirt, dirt should be in addition to the net, Tu personality vaseline oil. A cable installation, cable head after making, the cable head is fixed on the bracket and cable and bus contact surface should be smooth, contact surface character Vaseline coated can be connected and fastening, cable construction after should the cable compartment and cable trench packer;

- cabinet indirectly busbar connection, the switch cabinet along the arrangement direction are connected into a whole, check connected protection and grounding whether there are omissions, grounding circuit is connected and communicated, grounding resistance should be less than 1000p9, protective earthing resistance is not more than 453.

, secondary loop cable installation, cable by the mechanism of the left end of the penetration, Shun side wall into the relay room, received a corresponding terminal, construction should pay attention to the signal cable and terminal number don't leak wear or wear the wrong.

2, acceptance test and put into operation before the preparation work

(1) acceptance test item

According to the order information to check the cabinet installation of electrical components models, specifications are consistent;

And check the fastening piece is loose, found loose should be tightened;

Check bus connection, the contact is tight, such as poor contact, should be adjusted;

Manual operation of isolation switches, circuit breakers, mechanical interlocking procedures, such as 3 - 5 times, should be flexible and no hysteresis phenomenon, and should be accurate, the procedure is correct;

Check the mechanical characteristics of the circuit breaker, isolating switch, whether it meets the requirements of its own;

Check the two wiring is in line with the requirements of the drawings, in the main loop circuit, the two circuit through the action test, should be in line with the two wiring diagram

Requirements;

, main loop resistance measurement, due to the switch cabinet scheme, the resistance value is yet to be determined, tentative measurement site for the circuit breaker, circuit breaker does not exceed the standard value, was used to measure DC voltage method, pass to 100A DC current, measuring the voltage drop;

And secondary circuit insulation strength test and applied between the conductor and shell, AC 50Hz, voltage 2000V, 1min should be no breakdown phenomenon, the secondary circuit part of the electronic device, the test voltage is agreed upon by the manufacturer and user.

The main circuit of the power frequency insulation voltage test, in the relative and interphase, the exchange of 50Hz, according to the rated voltage of the switch cabinet, according to the GB311.1 value of 85% of the duration of the 1min should be no breakdown flashover phenomenon.

(2) put into operation preparation work

- site activities need to fill oil, lubricating oil should be injected;

Switch on control, signal, lighting and other power supply;

In isolation, the breaker is in a closing state, to the main bus power supply, which means that a forward line circuit breaker cabinet;

Close the isolation of the switch cabinet with a voltage transformer, check whether the voltage meter is correct, if the correct continue to go down;

On the lightning arrester, in the station with the transformer isolation and related auxiliary equipment to put into operation;

Turn on the feeder circuit breaker in order to check whether the current meter is correct or not.

3, maintenance and overhaul

(1) after the switch cabinet is put into operation, the monitoring and maintenance work is as follows:

To observe the main bus and electrical connection at the bus, such as bus overheating discoloration should be overhauled;

Observe the lighting, control, signal power supply is normal; record the number of circuit breaker action.

(2) maintenance

Switch cabinet maintenance, troubleshooting and periodic maintenance, troubleshooting is to prevent fault operation and to prevent the spreading of the accident, find fault or judge will appear in the immediately the fault parts overhaul and timely troubleshooting.

Regular maintenance, according to the operation of the provisions of the time, the maintenance of the contents are as follows:

Clean all parts of the dust, especially the dust on the insulation surface:

* maintenance procedure lock and mechanical interlock, the action is flexible and reliable, and the program is correct;

According to circuit breaker, isolating switch, operating mechanism and other electrical equipment for maintenance, debugging;

, check the electrical contact area, the contact is good and testing ground loop, keep continuous conduction;. The fastening screws and pins.

Packaging, transportation, storage:

1, packaging

(1) packing and marking switch cabinet should be in accordance with the provisions of XGN / 24BG.

(2) bus packed separately.

(3) before packing all conductive contact surfaces shall be painted with neutral Vaseline.

(4) the switch cabinet shall supply the following documents with the box

Product qualification certificate;

Packing list;

Installation instructions;

Main loop system diagram;

Accessories.

2, transport

(1) the switch cabinet can be unloaded and transported by forklift, crane unloading is also available.

(2) when handling is not allowed to tilt, upside down and suffered violent movement.

3, storage

(1) switch cabinets should be stored in a dry place;

(2) should prevent rain, to avoid damp.

(3) to switch out of the box, shall not remove the electrical components and parts.

The following information shall be provided to the user when ordering:

1, the main line scheme number and single line system diagram, arrangement diagram;

Two, the 2 circuit wiring diagram, terminal arrangement diagram, such as the terminal without arrangement diagram according to the manufacturer:

3, switch cabinet type of electrical components, specifications, quantity;

4, bus, bus support materials, specifications, or by manufacturing J provision supply;