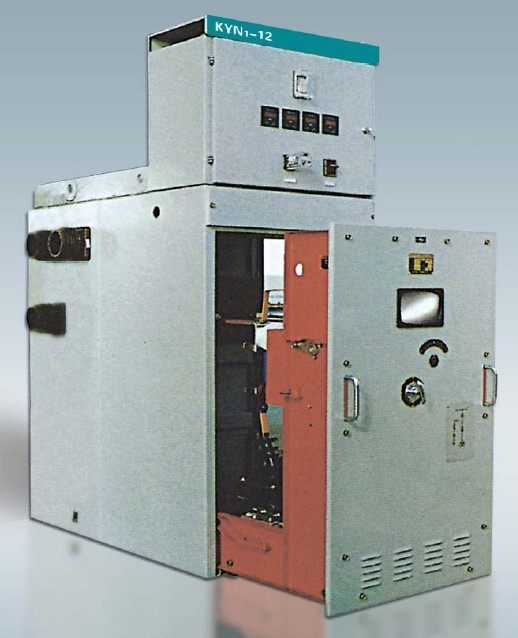

A, KYN1-12 high voltage vacuum circuit breaker Product Overview

KYN1-12, JYN2-12 series AC armoured shift type metal closed high voltage switch cabinet and is suitable for three-phase AC 50Hz, rated voltage 3.6-12VK, rated current 630-2500A single bus power system, as a power plant, substation () and industrial and mining enterprises to accept and electric power distribution equipment.

Handcart is the switch can be installed ZN28-12 type vacuum circuit breaker, the bottom is equipped with four roller, along the horizontal direction, and is also provided with a grounding contact guide device, a locking mechanism and hand truck out the hand-operated mechanism device can also depending on the user requirements, the installation of type SN10-10 less oil circuit breaker, operation mode, can be equipped with CD type electromagnetic mechanism, but also can be equipped with CT type spring operation mechanism of circuit breaker handcart, voltage transformer hand trolley, voltage transformer, arrester hand car, all transformer hand trolley, isolated handcart and grounding hand car and grounding trolley seven. With the width of the cabinet is 840mm, 1000mm, etc. various kinds of switch cabinet.

The main technical performance of the cabinet of the tender, are in line with the GB3906-35KV< AC metal closed Switchgear Equipment > standard requirements.

Two, KYN12 high voltage vacuum circuit breaker model and meaning

1, KYN12 high voltage vacuum circuit breaker of the main models

KYN1-12/630-25 KYN1-12/630-31.5 KYN1-12/630-20

KYN1-12/1000-25 KYN1-12/1000-31.5 KYN1-12/1000-20

KYN1-12/1250-25 KYN1-12/1250-31.5 KYN1-12/1250-40 KYN1-12/1250-20

KYN1-12/2000-40 KYN1-12/2000-31.5

KYN1-12/3150-40

KYN1-12/4000-40

Note: 40.5KV, 10KV this is the rated voltage. We usually refer to the 35KV, 12KV is the system line voltage.

2, KYN12 high voltage vacuum circuit breaker of the meaning of the model

Armored type K

Y shift

N indoor

1 Shenzhen Nortel electrical circuit breaker product design serial number

12 rated voltage (KV)

Z vacuum circuit breaker

630 rated current (A)

20 breaking current (A)

For example: KYN1-12/630-20, indicating that this is a KYN1 type indoor AC armoured shift type metal closed high voltage switch cabinet; the rated voltage of 12kV; rated current is 630A; breaking current 20KV.

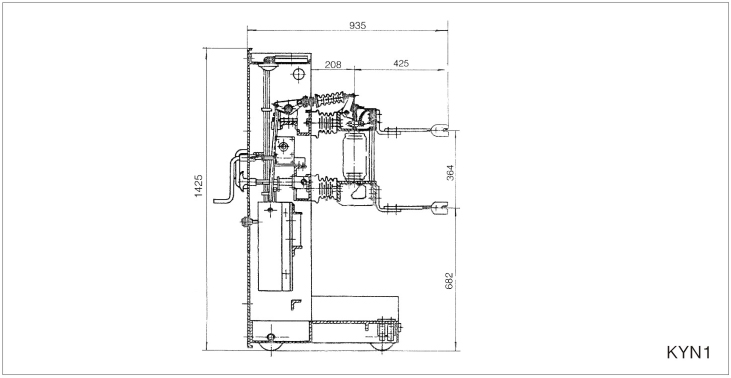

Three, KYN12 high voltage vacuum circuit breaker operating principle

Into the import and import and instrument and instrument, the structure of the product by the former cabinet, the cabinet after relay box, hand car and pressure relief device (cover) five parts. Before the cabinet, the cabinet after pressure relief device with bolt connection, relay box and cabinet through the shock absorber is connected. The former cabinet is divided into two parts, hand car room and second terminal room. After the cabinet is divided into two parts, the cable chamber and a main loop bus room. Above the plate separately welded and according to the overhead lines and cable lines, the left and the right contact, with very few cabinet composition distribution complete sets of equipment to meet different use requirements. This product can according to need to be attached to the standard bus bar bridge and two row cabinet is connected across the bus bar bridge.

1, front cabinet

Before the cabinet by the second terminal room and a handcart room is composed of three parts. Terminal room with doors can be opened, the installation and switch control circuit components. Cart room at the top is provided with a relief pressure device (cover), if the internal flashover accident, resulting in high pressure gas, pressure relief lift the lid open, to prevent accidents from expanded.

The two static contact and the protection mechanism are arranged on the top of the hand car room, and the two moving contact is installed on the top of the hand vehicle. As the hand vehicle enters, the two moving contact can be automatically controlled to ensure that the control circuit is switched on or off.

Before the bottom panel of the cabinet is provided with a connecting contacts and hand car recognition pin, limiting structure, bottom left open a secondary loop cable inlet and outlet hole, secondary cable through the hole into the terminal room, instrument box. And the right side is provided with grounding switch operation axle and interlocked with the rear lid and hand car. Before the cabinet is arranged at the rear part connected to the metal valve, preventing mistakenly charged interval. Left and right side plates with a valve lifting mechanism and a trolley positioning device.

2, after the cabinet

After the cabinet into a bus chamber and a cable chamber, a pressure relief device is arranged at the top and front cabinet cabinet after the same function, bus room on the left side of the panel is equipped with three bus through the insulating sleeve, with insulating sleeve, and insulation casing well, to prevent the expansion of the accident. The cross section of the main loop bus is 2 * (10 * 100) m square meters of double bus, bus room can hold three with a static contact epoxy resin or SMC material pressed contact box and support insulator. The cable compartment can be loaded three contact box or current transformer type contact box. The grounding switch is arranged on the lower end of the current transformer or contact box and the bottom is provided with a grounding bus, make equipment reliable grounding. A cable from the bottom out. The lower cover plate is provided with an observation window, easy to observe the running conditions of equipment. The cabinet support insulator according to user needs the sensor type insulator extraction voltage signal.

3, relay instrument box

Relay instrument box through four shock absorbers installed in the upper part of the front terminal cabinet room, to prevent the relay caused by vibrations misoperation. Meter box is provided with a panel can be opened, box is provided with a screen door, panel, a net door can be placed on the second element, wiring and maintenance are convenient and safe. Meter relay box upper part can according to the user request for additional 15 loops of small bus terminal.

4, hand car

The truck with steel plate bending and welding, the bottom is provided with a grounding contact device, hand car connected reliably in a working position. The hand car shake into the working position, panel will handcart room from the outside world, the handlebar room is no longer set handcart room door panel is arranged on the upper part of the observation. The window, the car is equipped with lighting, in order to observe the operation of circuit breakers and other equipment, the panel is arranged on the middle part of the position indicator. The handle and the mechanical coupling device, with the trolley is locked in position, test the position and function of the open position and at the same time. The mechanical and electrical interlock function of the hand car panel also. Equipped with an emergency brake button and closing position indicator. Also, according to user needs with the counter. The truck is arranged on the middle part of a worm gear type propulsion mechanism, the truck move smoothly and in the cabinet. The face plate is provided with a circuit simulation diagram and hand car import operation.

According to the user's requirements, the hand cart can also increase the travel switch, heater and other components.

5, interlocking

In order to ensure the safe and reliable operation of the equipment, this product is equipped with mechanical and electrical interlocking device, fully meet the requirements of "five prevention", that is to:

A, to prevent the error, the circuit breaker;

B, to prevent the load with a load, insert an isolated contact;

C, to prevent the charged grounding switch;

D, to prevent the grounding switch is not open before the circuit breaker;

E, to prevent into live space.

F, terminal room or instrument box door can be equipped with a program lock function of the conversion switch (by the user to choose), can prevent the error, the circuit breaker;

G, in the middle of the panel, only when the circuit breaker is in the state of the switch, can be transferred to and from the position, when the hand cart can push the cabinet or withdraw the cabinet to prevent the load from being inserted in the first isolation contact;

H, circuit breaker and grounding switch interlocking mechanism, only in military vehicles exit the cabinet body, the terminal room door charged display device indicating lamp is extinguished to use special tools the earthing switch on. Hand car in the working position, grounding switch operation axle hole is blocking the trolley panel, grounding switch don't switch on, can prevent with charge grounding switch;

Earthing switch on, hand car blocked block barrier can not enter the test position, job position, to prevent the earthing switch is not open before close circuit breaker;

I, after the cabinet is equipped with disassembly, under cover and lower cover plate is provided with a grounding switch interlocking device, only after the handcart extract and earthing switch on, cover can be disassembled., cover interlock can only be removed first, under cover, after the demolition of the upper cover. Assembly only after installed on the cover plate, and installed under the cover, then grounding switch to switch, preventing mistakenly charged interval.

J, each cabinet can be based on user needs, increase the mechanism of interlocking and electrical interlocking.

6, operating procedures

A, outage maintenance

When the product is in the running state, according to the following operation procedure:

(1) after receiving the power cut off of this product, the operation (with the program lock) switch or switch button, the breaker points;

(2) the position indication handle out of the position from the working position transferred to, according to the operation of direction indication pushing mechanism. The truck to pull out. Such as hand car with a mechanical interlock need trolley Panel mechanical interlocking device keys and transferred to the gate position, launched in military vehicles. At this point, you can the electrical and mechanical lock device of the key to get to operate other products, to remove the blocking between cabinet;

(3) the truck out of the cabinet body. After the voltage monitoring device of the three indicator lights, then insert the grounding switch operating lever, a special operating handle according to the cabinet before the lower right corner of the signs indicating the direction of the rotation, earthing switch on;

(4) remove the rear cover, and then remove the cover, this time, all the operation is completed, the product is in a state of power outage maintenance.

B, power supply

When the product is in the state of outage maintenance, according to the following operating procedures:

(1) the first to install the product after the cover, and then put under the cover;

(2) insert the grounding switch operating rod, and the special operation handle is sheathed on the upper right corner of the front cabinet to rotate in the direction of the direction of the lower right corner of the front cabinet;

(3) according to the position of the hand cart panel to move in and out of the position, the hand cart is pushed into the cabinet, and the pushing mechanism is operated according to the direction of the direction;

(4) operating conversion with program lock switch or button switch, the circuit breaker closing, finds its performance qualified so far;

(5) when receiving the instruction of the power transmission should be first conversion switch to the lock position, rotation position indicating the handle to the access position, operating the propulsion mechanism, the trolley is pushed to the working position and locked. Actuating switch or switch button, so that the circuit breaker closing. At this point, all power transmission operation procedure is completed, the product in the running state.

Four. Main technical parameters of KYN1-12 high voltage vacuum circuit breaker

1, KYN1-12 technical parameter table

Item unit data

25KA 31.5KA 40KA 20KA

1 rated voltage KV 12

2 rated current A 6301250

10006301250

20001250.2000

Three thousand one hundred and fifty Point Four Zero Zero Zero

3 rated short circuit breaking current KA 202531.540

4 rated short-circuit current (peak) KA 506380100

5 rated peak withstand current KA 506380100

6 4S rated short-circuit withstand current KA 202531.540

7 rated insulation level of power frequency withstand voltage (before and after the rated breaking) KV 42

Impact withstand voltage (rated open before and after) 75

8 rated operating sequence of sub -180S- -0.3S- points

9 mechanical life time 10000

10 rated short-circuit breaking current number of times 3020 times

11 contact distance mm 11 + 1

12 super stroke (contact and no spring compression length) mm 4 + 1

The 13 phase, closing three different period of less than 2 ms

14 contact bounce time of MS is less than or equal to 2

15 average split gate speed (just 6mm) m/s 1.1 + 0.2

16 the average closing speed of 0.6 + 0.2 m/s

17 gates

The maximum operating voltage of S is less than or equal to 0.06

Minimum operating voltage is less than or equal to 0.08

18 closing time is less than 0.2 s

19 the main loop resistance less than 50 ohm Mu = 40

20 the static and dynamic contact allows the wear and tear accumulation thickness mm 3

21 oil buffer buffer stroke 100-2 mm