HLGCS type low-voltage switchgear (hereinafter referred to as the device) is the two joint design group according to the design requirements of the Department in charge of industry, power users and design units to develop in line with national conditions, with high technical performance, able to adapt to the development needs of the market and low power with the existing imported product competition. Draw out type switch cabinet the device has been widely used. The power user device for power plants, petroleum, chemical, metallurgy, textile, power distribution system of high-rise building and other industries. In the power plant, such as a high degree of automation in petrochemical system, and computer interface places, as the three-phase AC frequency of 50 (60) Hz, rated working voltage 380V, (660), the rated current is 4000A and below, distribution in the power supply system, motor control, low voltage distribution of reactive power compensation device. Using the basic organizational unit form Formula, see Figure 1. Device is designed to meet the following criteria: 1. IEC439-1< and low voltage switchgear and Control Equipment >; 2. GB7251.1-2005< low voltage switchgear >; low pressure 3. JB/T9661-1999< draw out type switchgear >

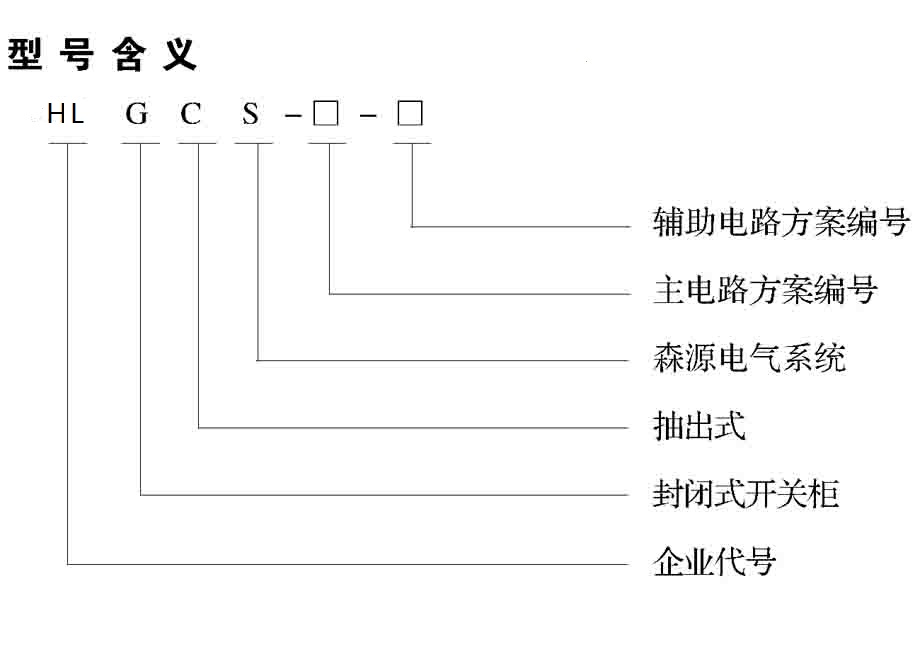

1 model meaning

2 use conditions

1 for indoor use, use the site altitude not exceeding 2000m.

2 ambient air temperature is not higher than +40 C, not less than.24 C -5 hours average temperature is not higher than +35.

3. Ambient air relative humidity at the highest temperature is 40 DEG C does not exceed 50%, to allow a larger relative humidity in low temperature: such as 20 DEG C to 90% should be taking into account the effects due to changes in temperature may occasionally produces condensation.

4 installation of the device with the vertical tilt of not more than 5 degrees Celsius, and the whole set of cabinet column is relatively flat (in line with the GBJ232-82 standard).

5 the device shall be installed in the absence of severe vibration and shock as well as insufficient to cause the electrical components to be subjected to the place where there should be no corrosion.

Users have special requirements, you can consult with the manufacturer to resolve.

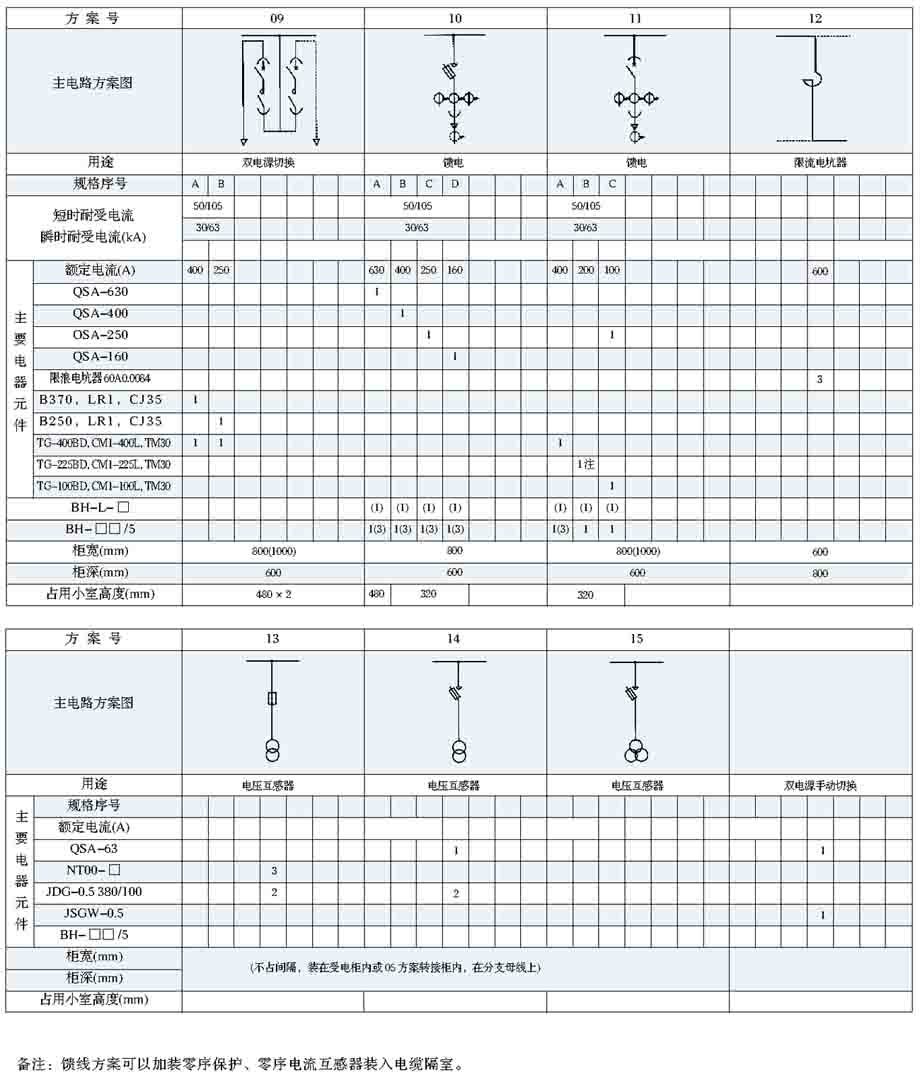

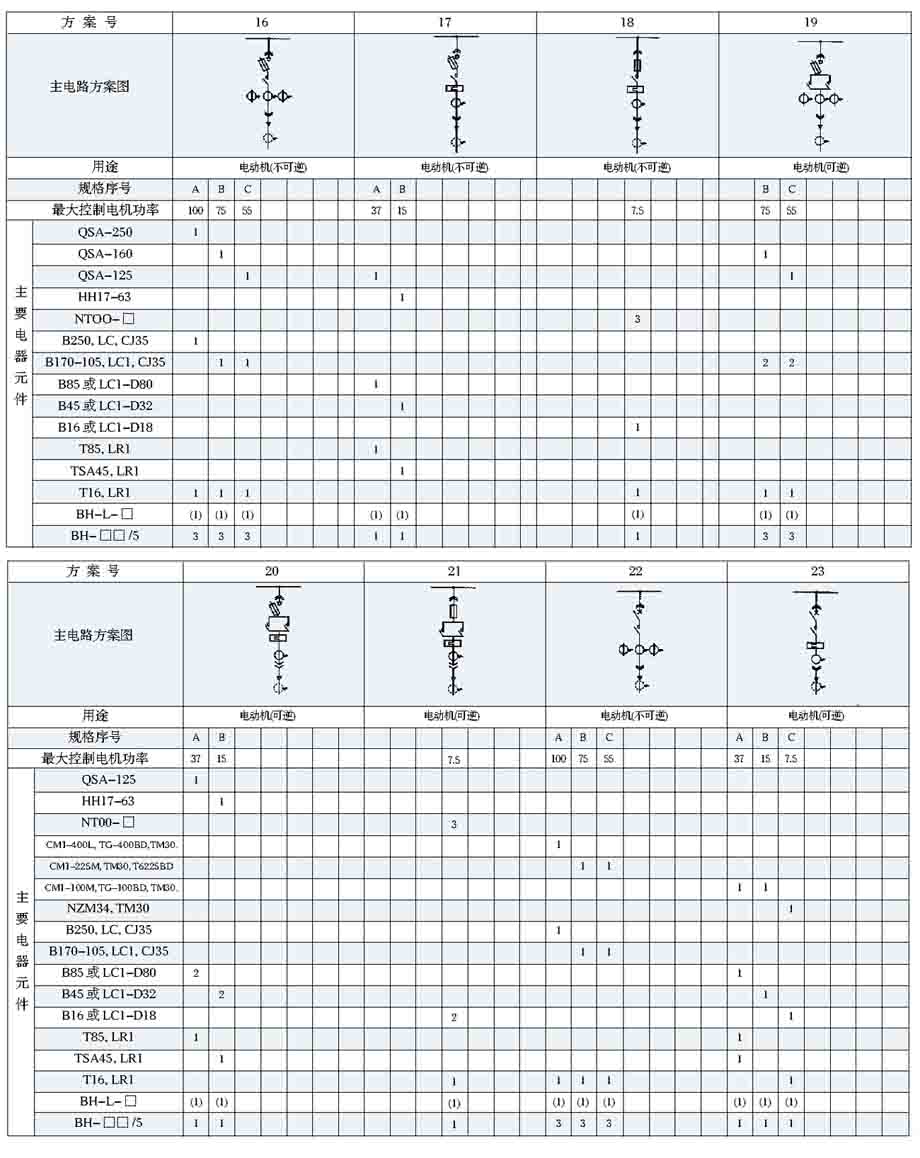

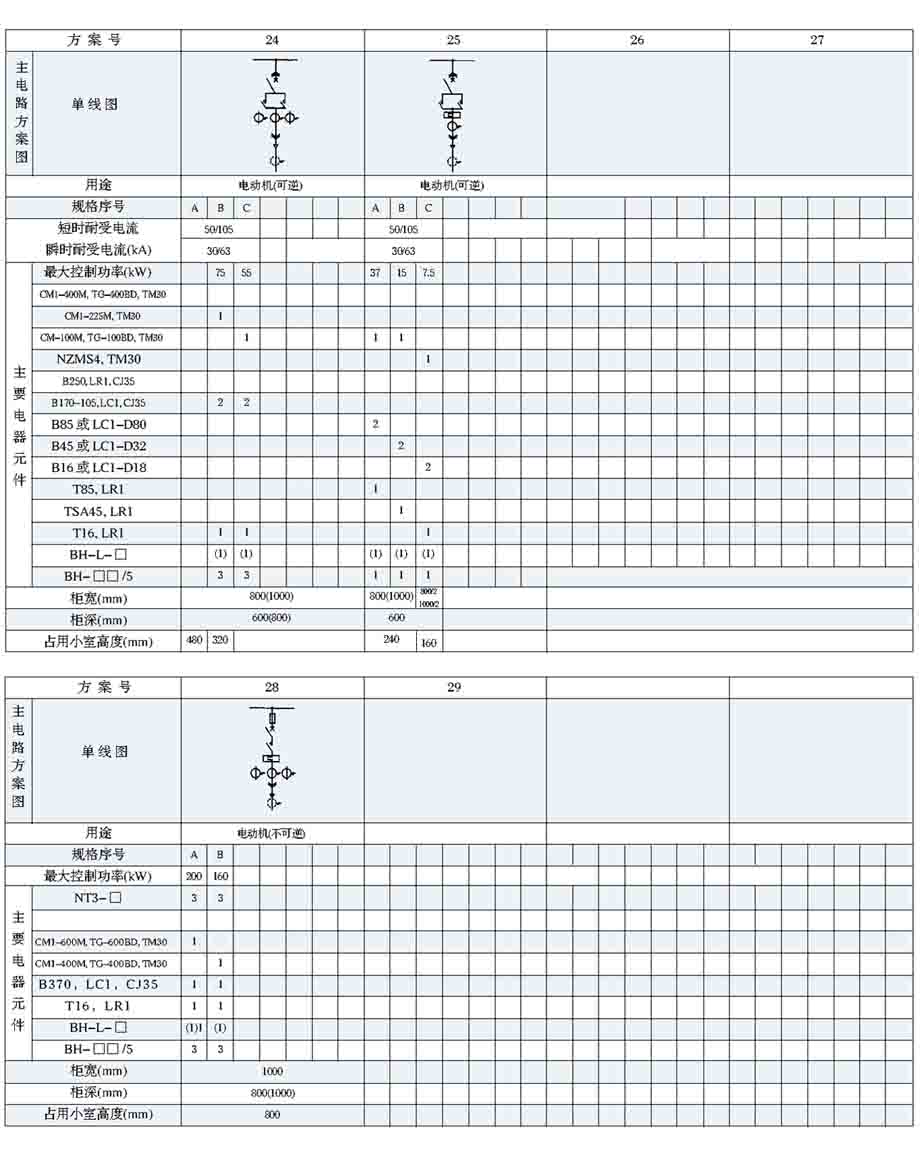

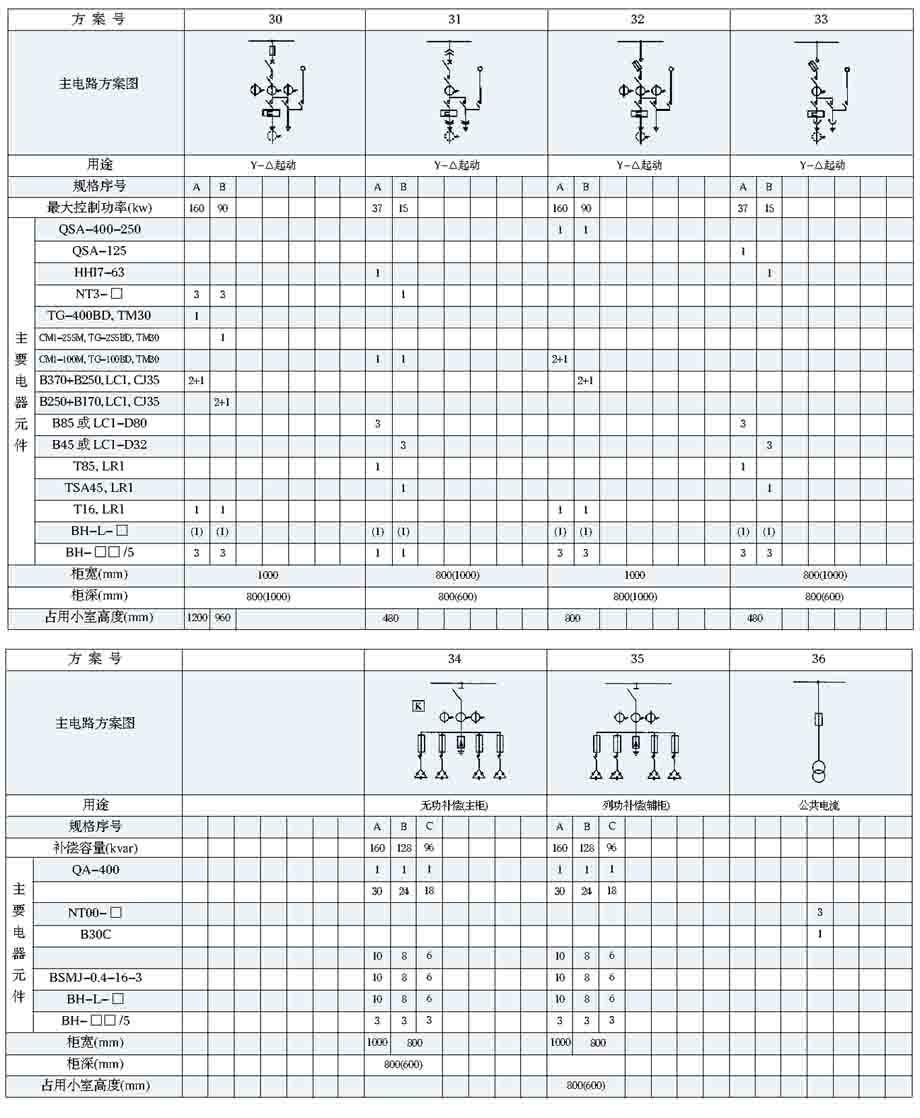

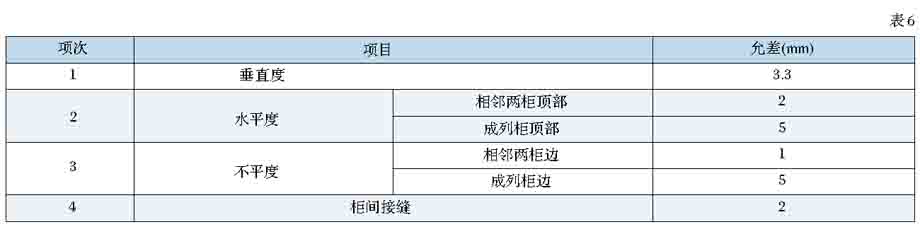

3 main circuit diagram

4 bus

A bus or bus bar

For improving the dynamic thermal stability and improve the contact surface temperature rise of bus, the device all adopt TMY-T2 series of hard copper, copper connections must lining tin. It is recommended to use full-length Tang tin, also can choose the length of silver plated copper bus bar.

1 level busbar

Horizontal bus in the rear of the switchgear busbar compartment, 3150A and above is under the double layout, 2500A and below for single-layer arrangement, each phase consists of 4 or 2 bus composition, greatly improving the bus short circuit strength. Copper bar of the parent level device selection as shown in Table 3.

2 vertical busbar

The vertical bus bar used in the drawer cabinet adopts the "L" - shaped hard copper tin bus.

L bus specification (mm): (high * thick) + (bottom * thick) (50*5) + (30*5) rated current 1000A,

3 neutral grounding busbar

Using hard copper. Through the level of neutral grounding line (PEN) or ground + neutral line (PE+N) specifications are shown in Table 4

Selection of main electrical components

* the specifications of the vertical PEN line or PE+N line in the device are all selected by 40 * 5

The equipment is mainly used in the advanced technology, and the introduction of the technology has been able to mass production of electrical components.

1 main switch

630A and above the power supply line and feeder switches, the main selection of AH series, you can also use DW45, DW40, DW48 series, AE series, 3WE or ME series, that is necessary, can also choose to import the MT series or E series.

2. Below 630A feeders and motor control switch, the main choice of TG series, CM1 series, molded case switches can also choose four nzm series, tm30 series moulded case circuit breaker.

3 AC contactor, the main selection of B series, LC1 series, 3TB series of contacts and with the matching of the thermal relay, interlocking mechanism.

4 current transformer adopts Hangzhou bi'aiqi Electric Appliance Co. Ltd BH series.

5 fuse selection high breaking capacity of the Q series of knife fusion and NT00 series.

6. To improve the dynamic stability of the main circuit, design the GCS series of special CMJ combined bus bar clamp and insulating support member, with high strength, flame retardant synthetic material thermoplastic molding, high insulating strength, good self extinguishing properties, unique structure, need to adjust is building blocks that can adapt to different specifications of the bus.

7. In order to reduce the functional unit of the spacer plate, connectors, cable head temperature rise, removed from the GCS cabinet dedicated switching, and similar products of production compared adapter heat capacity increases, the temperature rise is decreased.

8. If the design department according to the needs of the user, selects the performance more excellent, more advanced technology of new type electrical apparatus, due to GCs cabinet series has good versatility, not due to the update of electrical components, resulting in difficulties in manufacturing and installation.

Structure characteristics

1 the main frame of the device is 8MF - shaped steel, the frame is assembled with two kinds of structure, and the main frame is provided with a modular hole E=20mm.

2 each function room is strictly separated, and its compartment is mainly divided into function unit room, bus bar room and cable room. The function of each unit is relatively independent.

Dimension series 3 device for cabinet as shown in Table 5

4 function unit

The high modulus of A. drawer is 160mm, which is divided into units, 1 units, 1 units, 2 units, 3 units of five dimensions series, unit circuit rated current 400A

And below.

The B. drawer changes only the height of the size, its width, the depth of the same size. The same functional unit of the drawer with good interchange.

C. each MCC cabinet up to install an 11 unit drawer or 22 1 / 2 unit drawer. The drawer unit above the back plate.

D. drawer import line according to the same standard connector type structure with different number of the current size.

1/2 E. unit drawer and cable compartment of the transfer using the back plate structure ZJ-2 type adapter.

The switch of the f. unit drawer and the cable compartment is of the same size rod type or tube type structure ZJ-1 adapter according to the current distribution.

G. drawer panel has the obvious signs of the location of points, closing, testing, taking out and so on.

H. drawer unit is equipped with mechanical interlocking device.

5. Feeder cabinet and the motor control cabinet is provided with a special cable compartment, functional unit and indoor cable cable connection through the transfer or transfer the copper bar, both to improve the use reliability of the cable, and greatly the users of cable installation and maintenance. Cable compartment has two width (240mm and 440mm) can be used, depending on the number of cables, cross section and user convenient maintenance requirements for installation and.

The function unit of the 6 device is the number one unit of the auxiliary contact and the 32 pair, the 1/2 unit is 20 pairs, which can meet the needs of the user and the computer interface.

. considering the economy of dry-type transformers in common security and oil immersed transformer, the device can be conveniently the dry-type transformers and composed of a group of columns, also can be connected conveniently with a low-voltage busbar of oil immersed transformer.

8 drawer as the main body, at the same time with the extraction and fixed, can be mixed combinations, arbitrary selection.

9 device according to three-phase five wire system and three-phase four wire system design, design department and users can easily choose PE+N or PEN mode.

5 device characteristics

1. To improve the transfer of heat capacity, greatly reduced due to the connector of temperature rise to connector, cable head, baffle brings additional temperature rise.

2 between the functional unit, the separation between the room is clear, reliable, not because of a failure of a unit and affect other units of work, so that the fault is limited to the minimum range.

3 bus flat arrangement makes the device dynamic, thermal stability is good, can withstand the impact of 80/176KA short circuit current.

4 MCC counters single cabinet number of circuits to 22 times, fully consider the needs of large single machine capacity power generation, petrochemical systems and other industries automation electric door (machine) group.

5 device and the connection of the external cable in the cable compartment is completed, the cable can be up and down out. Zero sequence current transformer set the cable compartment, so that the installation and maintenance is convenient.

6 installation and use

The product reaches the place of receipt, first of all should be check the packaging are intact, found that the problem should be timely notification of contract to the relevant departments do a good job in the record business, common reason analysis, prepare visa and deal with the aftermath. For not immediately install the products should be according to the normal conditions of use and electrical equipment for temporary safekeeping rules put in their proper places, safekeeping.

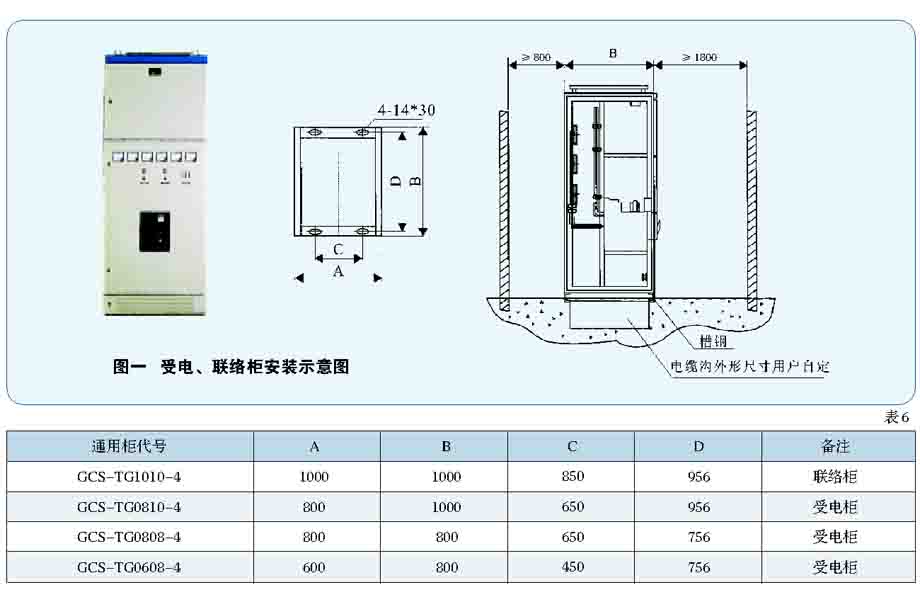

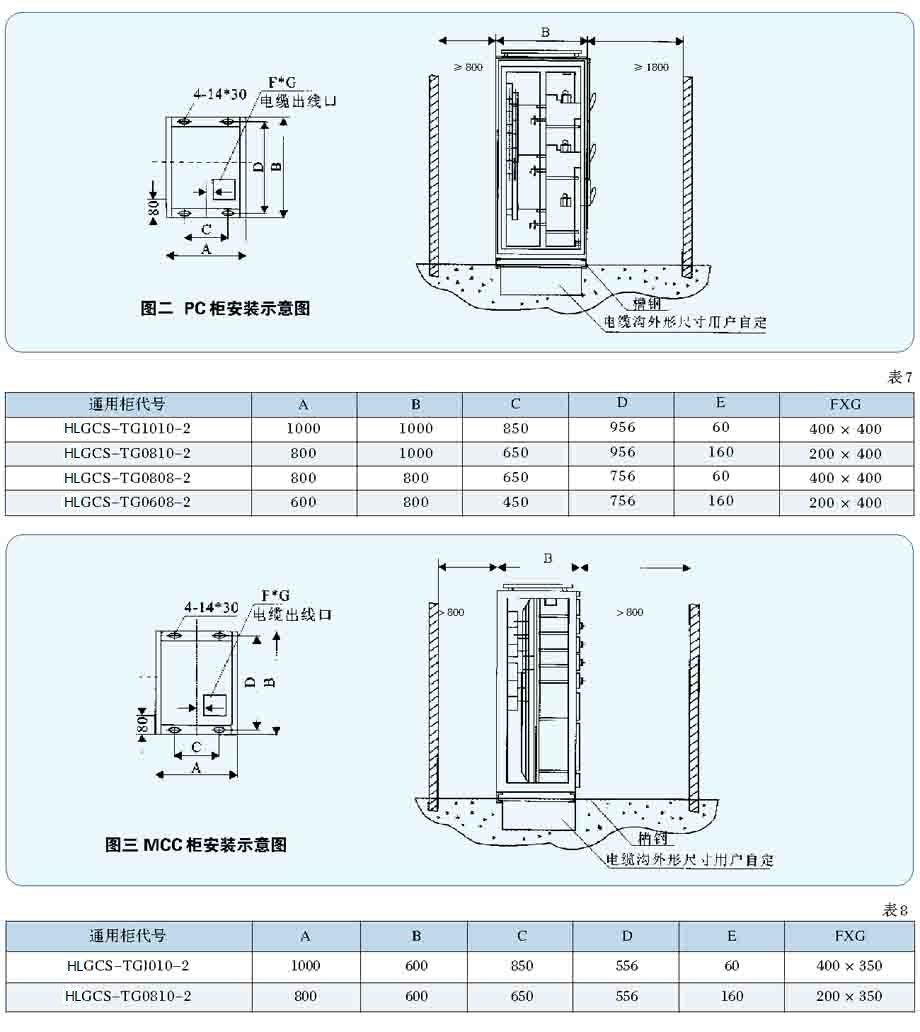

Product should be installed according to the schematic diagram of (see Figure L ~ Figure 3 and table 6 to table 8). The foundation channel steel and the fixed mode of the bolt bolt by the user owned. Busbar connection such as surface due to the transport, storage and other reasons not flat to flat is connected with the fastening.

The 2 device installed individually or when the verticality and gap between the cabinet and counter roughness deviation should comply with the regulations in Table 6.

The inspection and test of 7 product installation after money

1 check counter paint or other covering materials (such as plastic) have been damaged, the cabinet is clean and dry.

2 the operating mechanism of the electrical components is flexible and should not be stuck or damaged too much.

3 the main auxiliary contact of the main electrical equipment is reliable and accurate.

4 pulling out of the drawer or drawing mechanism should be flexible, portable, free of blocking and touching.

5. Drawer or out of the type structure of the dynamic and static contact the center line should be consistent, the contact should be tight. Lord, auxiliary contacts of the insertion depth should meet the requirements. Mechanical interlock and electrical interlock device should be correct, atresia or rescission shall be reliable.

6 the same size of the drawer should be able to facilitate the interchange, no card resistance and collision phenomenon.

7. The drawer and cabinet grounding contact should be close contact, drawer when pushed, drawer connected to contact the main contact to contact, pull connected to contact main contact disconnect.

8 meter scale setting, transformer and polarity should be correct.

9 fuse core specifications should meet the requirements of engineering design.

10 the rated value of the protection and the whole set shall be correct and reliable.

1000 to measure the value of insulation resistance with 11 MB of European meter shall not be less than 1MW.

12 the connection of each bus should be good, the insulation support, installation and other accessories should be installed firmly and reliably.

8 use note

1. The device is not against the wall installation, positive operation, double-sided repairs of low-voltage distribution cabinet. Cabinet maintenance channel and a cabinet door must is the assessment of qualified professional people can enter or open operation, inspection and maintenance.

2. Air circuit breaker, molded case circuit breaker after several minutes, especially through a short circuit, after will make contact local burn and produce carbon material, so as to increase the contact resistance, circuit breaker according to instructions for maintenance and repair.

3 after installation and maintenance, we must strictly check the compartment between the functional units of the isolation between the status of the device to ensure good functional separation of the device to prevent the expansion of the fault.

9 ordering instructions

1 the full model of the product includes the main circuit and auxiliary circuit;

2 combination sequence diagram of the main circuit system;

3 auxiliary circuit electrical principle;

4 cabinet components list;

5 circuit in the voltage, current, time setting parameters;

6 other special requirements which are not in conformity with the normal use of the product.